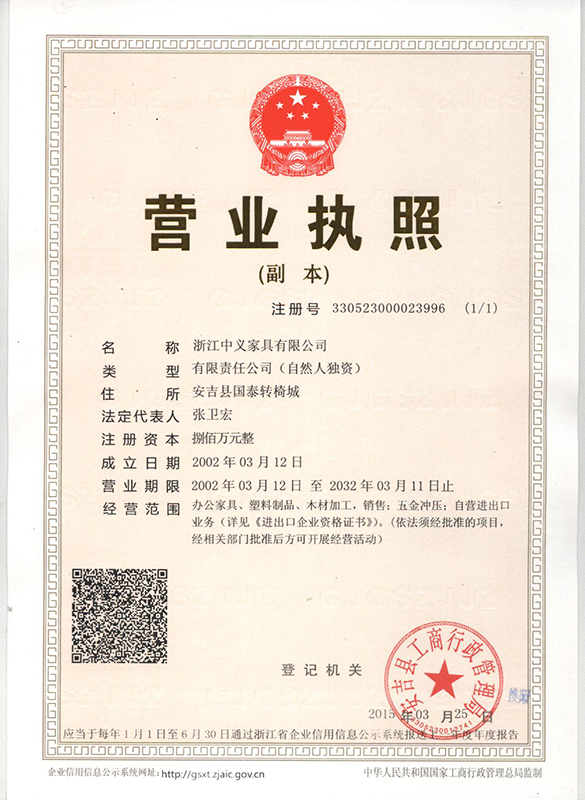

Zhejiang Zhongyi Furniture Co., Ltd. was founded in 1985,with registered capital of 800 million yuan, through more than 20 years' steady development, now our factory covers an area of 31 acres.,we have 22sets big injection machines,5 sets blow molding machine,three production workshop, equipped with full set of advanced chair testing lines.With more than 230 employees, we mainly deal with the production and marketing of chair accessories, plastic chairs, auditorium chairs, injection plastic parts etc.Total around 2000 kinds product models.

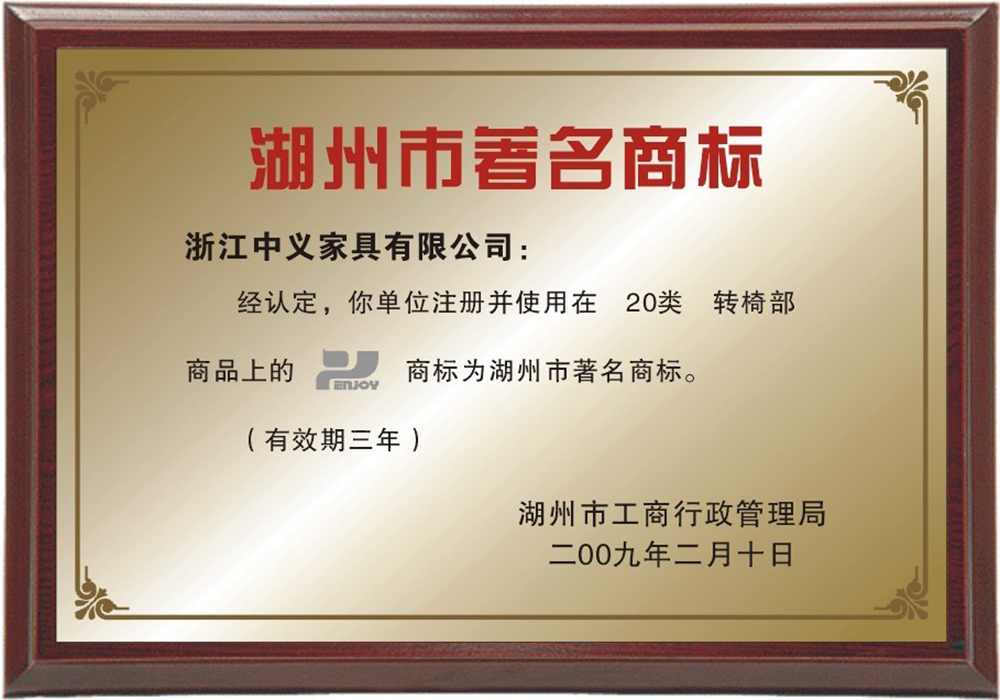

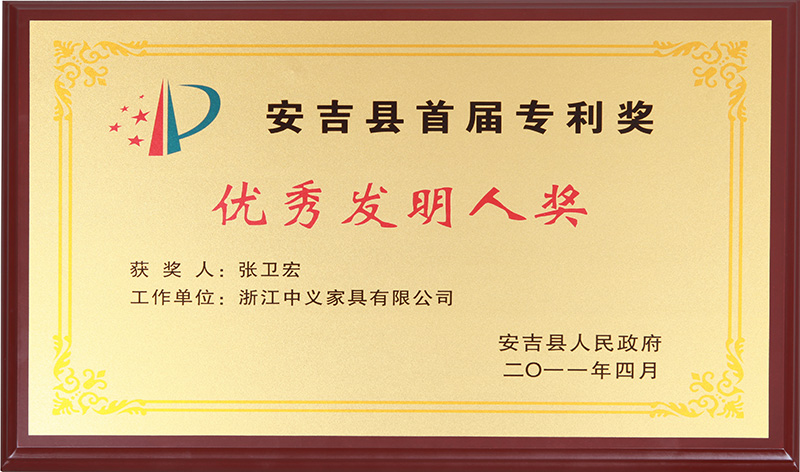

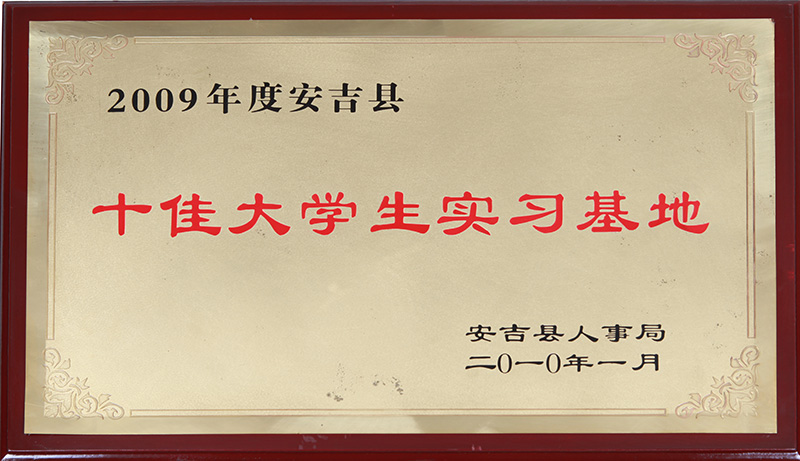

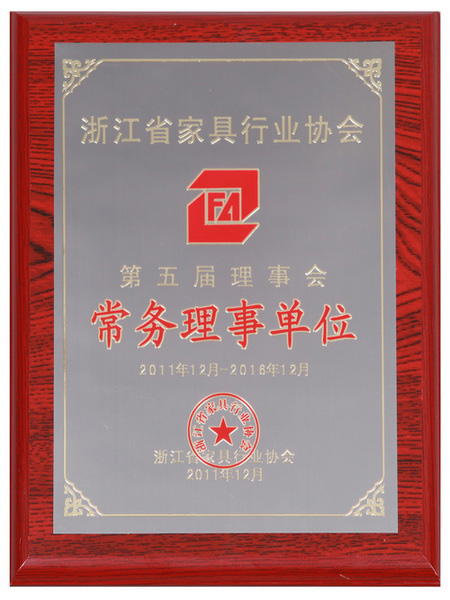

Our company have passed ISO 9001:2008 quality management system certification also National Cleaner Production Acceptance. We are one of the top 100 enterprises in Anji County ,have obtained one national honor, 19 provincial honor, 68 city/county level honor.With integrity and strong design, development and manufacturing capabilities,we provide high quality,low-cost products and services to our customers both at home and abroad,our chair products have obtained 72 national patents.Zhongyi has established pioneering and innovative operating principles, comply with business ethics, focus on talent introduction and training, ensure employees' benefit,establishing a perfect salary, reward, social insurance system and the operation safety guarantee system,fulfill our social responsibilities, be enthusiastic about social welfare undertakings, focusing on environmental protection and the promotion of sustainable development. We adhere to the 'customer satisfaction, our pursuit' for the concept,serve each customer piously, welcome to Zhongyi!

浙公网安备33052302000377号

浙公网安备33052302000377号